Environment

We are protecting our planet by reducing our carbon emissions

Paving the way for net-zero

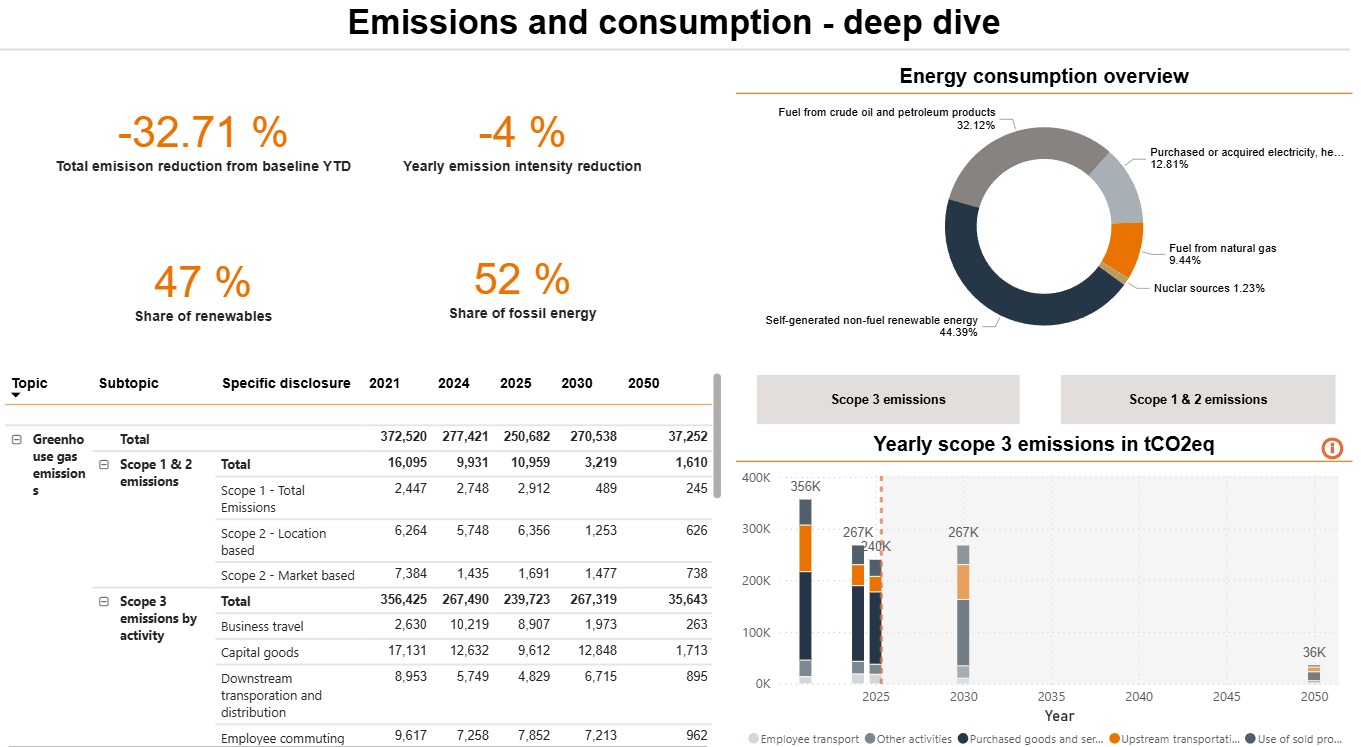

In November 2022, the Science Based Targets initiative formally approved our targets to reduce scope 1 and 2 carbon emissions by 80% by 2030, and scope 3 emissions by 25% by the same year.

In November 2022, the Science Based Targets initiative formally approved our targets to reduce scope 1 and 2 carbon emissions by 80% by 2030, and scope 3 emissions by 25% by the same year.

Driven by our decarbonization efforts, in 2025, scope 1 and 2 emissions were 53% lower than our 2021 baseline, while our scope 3 emission reduction goal were already reached with a 33% reduction compared to the baseline. Read more about our decarbonization strategy in our 2025 Annual Report.

Explore our emissions and energy consumption in the report below.

Circularity

Circularity is an integral part of our sustainability strategy. As a manufacturing company in the technology space, challenging the prevailing linear business model within our industry mitigates long-term environmental risks to our company and society as a whole.

Through our circularity efforts, we aim to:

Pursuing circularity presents profound challenges to many parts of our business. It starts with design, which is the key enabler for circular use of products and components.

Beyond that, we focus on building the required logistics, offering circularity-linked services and entering the market for second-hand products.

Resource inflows

Our use of resources and circular economy metrics are illustrated above and provides detailed insights into how we are doing in this area.

We design our hearing, audio and gaming products to use fewer virgin resources andkeep materials in circulation for as long as possible. Our approach focuses on:

- What goes into our products (resource inflows)

- What happens when products and packaging leave us (resource outflows)

- How long our products stay in use (repairability and lifetime)

Since 2021, we have worked towards a voluntary design target: for all newly developedproducts, at least 50% of the total weight of mechanical parts (such as plastics,metals, fabrics and other non‑electronic components) should be made from recycled orrenewable materials, unless this is not feasible for technical or business reasons. This requirement is integrated into our product development process so that new products areassessed against it before launch.

We are gradually replacing fossil-based and virgin materials with recycled andsustainably sourced alternatives:

In 2025, 26% of the materials used across our full product portfolio were sustainablysourced bio‑based materials, meaning we exceeded our short‑term 2025 target of 25%. We increased the share of recycled content in our products and packaging from 2%in 2024 to 3% in 2025.

We raised the share of FSC®‑certified materials in our packaging from 50% to 58%,supporting responsible forest management.We aim to keep materials circulating when products and packaging reach end of life:

- Around 70% of the content in our products is made from materials that are recyclablein principle

- Around 89% of the content in our packaging is made from recyclable materials

Circularity is also about using products longer. For our devices, this means:

Designing for durability, so products can withstand daily use over many years.

Focusing on reparability where feasible, for example by enabling replacement of selectedcomponents and accessories, and by working with professional service partners andhearing care providers to extend product life.

Designing for sustainability

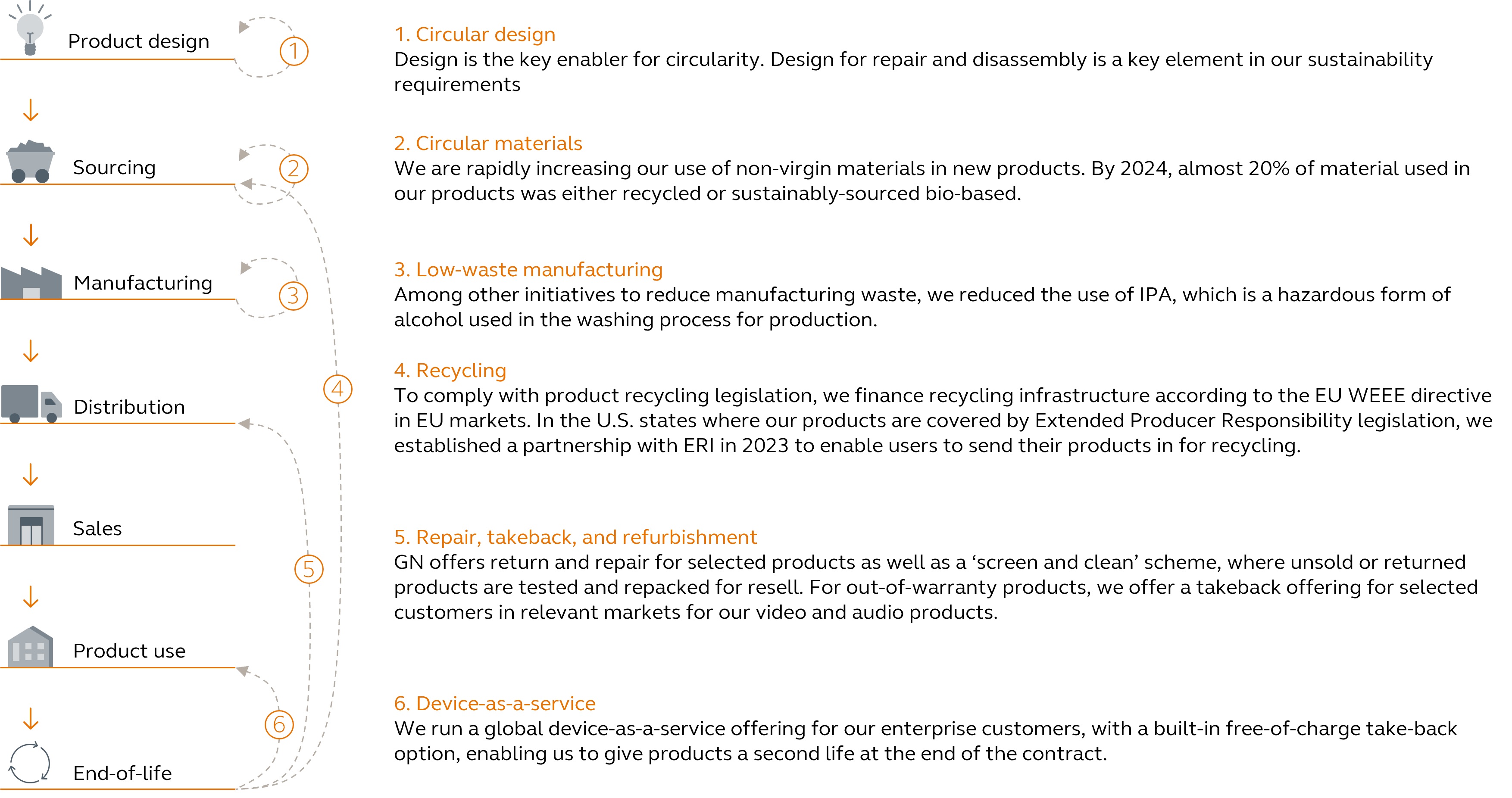

Sustainability in the product lifecycle

Sustainability is a key consideration in how we design, manufacture, and transport our products.

We consider sustainability in every life phase of our products, from their inception to their end-of-life, which you can also see from the graphic overview.

In product development, we use non-negotiable hard requirements largely based on compliance, as well as areas where we seek to maximize the positive environmental impact by pushing the boundaries. Our approach is data-driven, using product-level life-cycle assessments (LCAs) of existing products to optimize for decarbonization in subsequent products. TCO Certification is a minimum standard for relevant products.

To ensure that we follow the highest standards in product sustainability, we have assessed the relevance of a wide variety of sustainability certifications.

To ensure legitimacy, we applied two criteria when selecting certifications to strive for: full value chain coverage and based on a standard developed independently of GN.

TCO Certified was the only certification that matches both criteria. Many of our Jabra products are certified by TCO Certified. In 2023, SteelSeries' Arctis Nova Pro Wireless became the first gaming headset in the world to become TCO Certified.

As TCO Certified develops standards for additional product categories such as video, we will strive to get more products certified. See a full overview of TCO Certified GN products (filter the search by Jabra or SteelSeries).

Product life-cycle assessments (LCAs)

We regularly conduct product LCAs to calculate the carbon footprint of our products. The purpose of these LCAs is twofold. First, LCAs improve transparency about the carbon footprint of products, supporting our customers to improve their carbon accounting and select products in accordance with their own sustainability ambitions. Second, they reveal how we can best decarbonize products by identifying ‘carbon hotspots’.

Our LCAs are externally verified by Bureau Veritas as meeting ISO standards 14044:2006 and 14067:2018. As input data, we use bills of material, supplier-specific material, manufacturing and distribution data, as well as product power consumption data and marketing data for the use phase.